BRE Racing Engines

Accelerate to the front!

BRE Racing Engines

Accelerate to the front!

Quarter Midget Engine Program

At BRE we take precision workmanship to extreme levels. We carefully choose the best parts and pieces that go into one of our engines while assuring every engine meets the rules for each class or division they are raced in. We use state of the art equipment to test, inspect, flow and prepare our parts before machining our engine components to the highest standards.

New stock engines at BRE - We first start by running each stock motor on the dyno for 15 minutes at wide open throttle to allow for a break in of and to stress relieve the engine block.

After break in, the engine is disassembled and all the components are analyzed for wear and dimensional size. We then perform all the machining and blueprinting per BRE racing engine requirements, replacing any components we find that are not perfect choices for our engines.

After the final engine assembly, the engine is dyno tested and tuned until the maximum horse power specifications are achieved for each individual engine we build. Every engine must be matched for the track and conditions it will be competing in. We take the time to adjust and tweak every engine combination to assure it performs to the highest standards, based on your particular needs. We then prepare the engine for post testing running and shipment.

Every engine is shipped with a technical spec sheet on how to maintain and tune the carb for various racing conditions. At BRE we do not just stick your engine in the box and ship it, instead we make sure you have the information you need to have our engine perform just as well for you as it did in our shop.

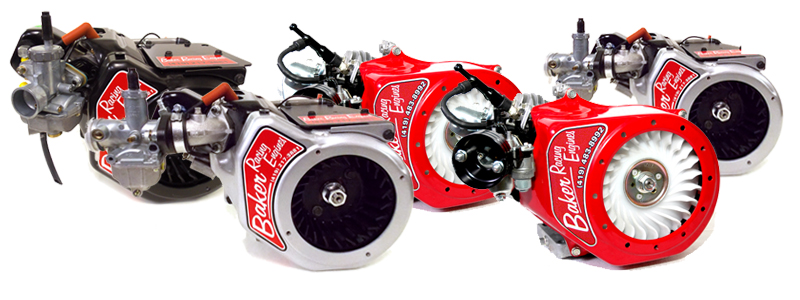

QM Engine Line Up

BRE offers only the best in QM engines, whether you need a Briggs Animal, Honda or World Formula Engine, we have the perfect engine for you. Every BRE Engine built for competition in Quarter Midgets is built to exacting standards.

We attend many USAC events each season, allowing us to stay on top of the racers' needs and make sure our product is the best we can build for them, each and every race weekend. |